Lenze at SPS

We deliver the best motion control solutions for your machines

Experience our motion control solutions, which combine in-depth application knowledge with powerful servo and drive technology for any speed, number of axes and architecture.

With Lenze, you get application-specific motion control for high-precision positioning, dynamic handling and modular automation solutions – tailored to every manufacturing requirement. Our technology and intelligent software combine precision, energy efficiency and cost-effectiveness – from sensorless control to intelligent axes for the highest cycle rates. Open interfaces, integrated safety and consistent engineering enable fast implementation, flexible scaling and long-term productive machines.

Experience MotoGP and Lenze Motion Control for yourself

If you want to step on the gas at the SPS, there is no way around our MotoGP simulator.

Visitors to the Lenze booth can experience for themselves what professionals normally use for training – with full dynamics, precision and five perfectly coordinated axes for sloping, drift, incline and accelaration. The simulator from sevensim demonstrates Lenze's motion expertise in its most impressive form thanks to the c520 motion controller, integrated position control, Safety STO, geared motors with encoders, direct drive technology and Lenze Selection SNR axis. The entire system was designed with the EASY System Designer – a central element of the Lenze Engineering Tools.

Experience at the SPS how much drive there is in Lenze VFDs.

All Lenze frequency drives combine a common DNA for maximum flexibility – whether inthe control cabinet, on the wall or directly on the motor.

The focus is particularly on the new i650 motec, the next generation of decentralizeddrives. With integrated Logic PLC, positioning and IO-Link Master, it replaces controlcabinets, reduces costs and, in combination with IE5/IE6 motors, combines maximumperformance with energy efficiency.

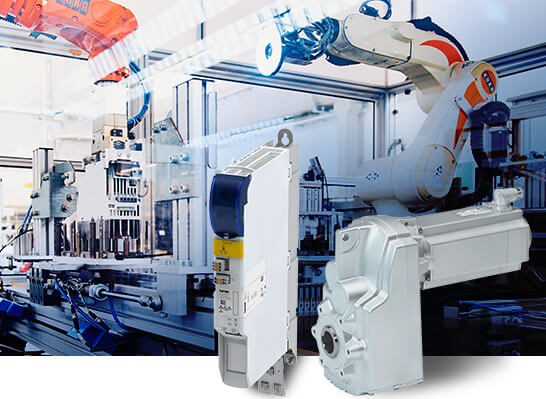

Lenze's servo portfolio combines dynamics, precision and scalability.

Our servo drives combine dynamics, precision and scalability. With integrated engineering and the Lenze FAST Application Software, they offer a strong basis for modern machine concepts.

In focus: the i950 multi drive – the next evolutionary stage of the i950 servo drive platform for modular drive systems. Thanks to its integrated DC rail system, high power density and flexible architecture, it reduces wiring work and creates new possibilities for compact multi-axis applications.

Electromechanics in top form

From simple to complex – with our comprehensive electromechanical modular system, we deliver the best solution for every application.

Motors, gearboxes, drives and system cables work perfectly together and open up a wide range of solutions: from standard to low-backlash, from energy-efficient to high-performance. In combination with decentralized electronics such as the i550 & i650 motec, you reduce cabling and installation costs – and gain investment security thanks to efficiency classes up to IE6 and a wide variety of sizes and gear ratios.

The new m650-F asynchronous motor

As the successor to the successful Lenze MF motor and a further element of the Lenze motor platform, it is specially optimized for operation with frequency drives.

Fully optimized for variable-speed applications: a compact, efficient and dynamic asynchronous motor that sets new standards in machine automation. It is two sizes smaller than conventional motors, with a large speed setting range (1:24), high overload capacity and robust design. This reduces variants, increases flexibility and sets new standards in machine automation. Together with gearboxes and frequency drives from Lenze, the result is a particularly compact, reliable and powerful drive system.

Cyber Security

Protects machines and know-how

Our automation products always have cyber security functions in-built to ensure that your machines, systems and plants comply with the NIS-2 directive and the Cyber Resilience Act (CRA). We support you in creating your security concept and live security by design – our development processes are based on the known standards and norms.