Integrated cyber security - to secure your machines

In the context of digitalization and industrial development, cyber security is becoming increasingly important. Meshing IT and OT creates new areas of attack, as not only IT but also machines and production systems are becoming targets for cyber attacks. These attacks can cause production downtime, machine standstills and data loss.

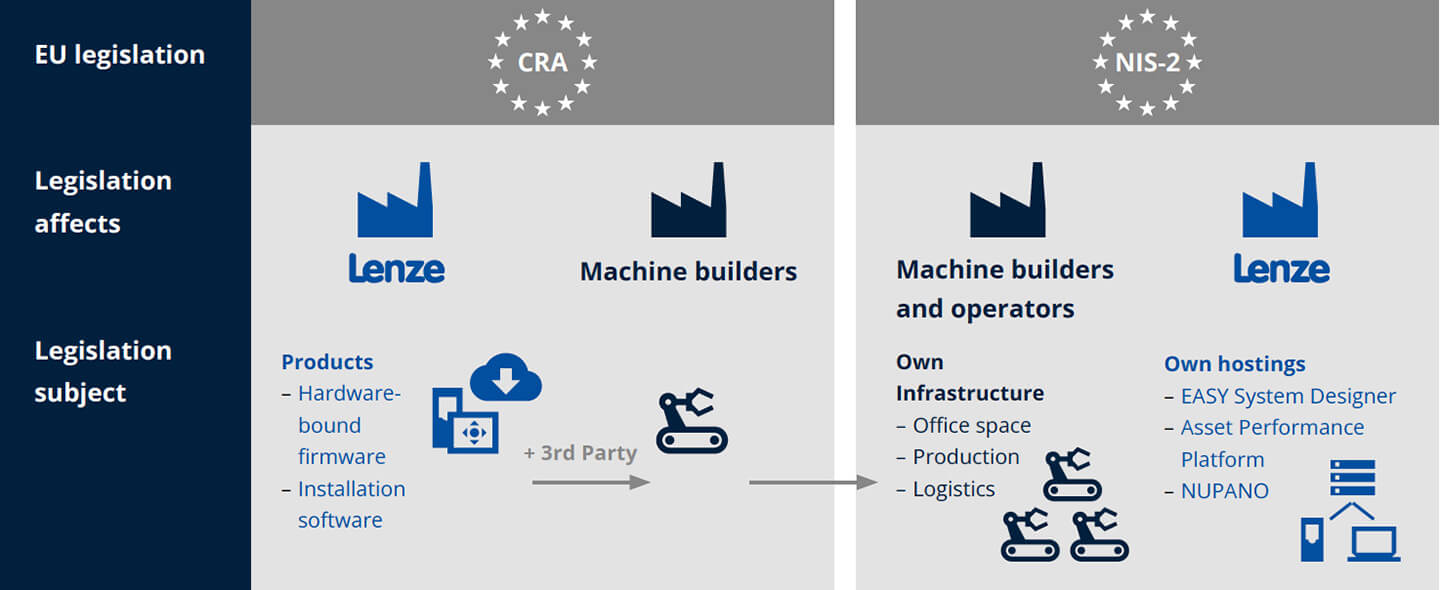

Machine builders and operators must protect their expertise and the availability of their machines and systems against cyber attacks. The implementation of the NIS-2 directive and the Cyber Resilience Act (CRA) will make this even more urgent.

With over 1,000 projects per year, we are an experienced partner for automation systems, digitalization and cyber security. We support you in designing your cyber security concept and, with the help of our solutions, increase the cyber resilience of your applications. This minimizes the risk of downtime.

We live security by design and our development processes follow the known standards and norms, such as IEC 62443. In addition, we are already taking the Cyber Resilience Act (CRA) into account and are working on fulfilling the criteria of Security Level 2 according to IEC 62443-4-2.

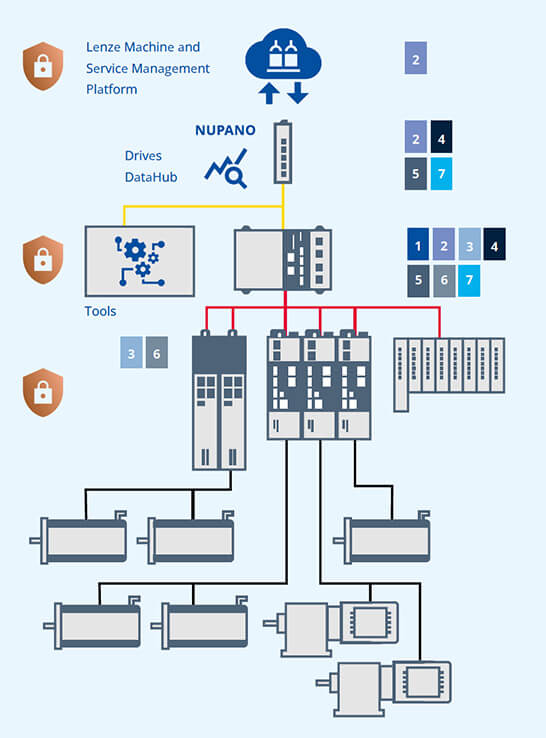

Our cyber security solutions

Encrypted communication: secure communication via OPC UA on our controllers

Backup and restore concepts: Management and recovery of apps, firmware and applications with Engineering Tools

Authentication of users and services: access protection for Drives DataHub and controllers

Firewalls: Restricting access routes into the automation system with firewalls in the x500 and controllers

Encryption of sensitive data: Coding of the PLC program in the PLC Designer and controllers

With the Cyber Resilience Act (CRA), the EU will require all manufacturers of products with digital elements—including machine builders—to report actively exploited vulnerabilities starting in September 2026. Starting in December 2027, structured vulnerability management will be mandatory. The goal is to identify cybersecurity gaps early on, assess them appropriately, and fix them promptly.

What does this mean for mechanical engineers in concrete terms?

In future, mechanical engineers will have to:

- Continuously monitor the vulnerabilities in their machines and the components used

- Establish clear processes for evaluating and sharing security-related information

- Inform their customers about relevant cyber security risks in their machines

The following applies: Responsibility does not end with your own product – information from suppliers must also be actively obtained, evaluated, and documented.

A glimpse into the future... “Less is more”

In a world where cyber security is becoming increasingly critical, fewer activated functions mean fewer attack targets. Products that require users to activate functions and interfaces are becoming the standard. Lenze is adapting to this development and will deliver products in a smart “secure-by-default” configuration in future.