Close cooperation between businesses, politics and science in Germany is creating an innovative, digital ecosystem for factory equipment suppliers and operators. Lenze is highly engaged in this initiative along with 46 partners. The system is based on the principles of Catena-X, the data room for the automotive industry and the Industry 4.0 platform.

The aim is to strengthen the competitiveness of the industry by creating a secure digital data space for the exchange of industrial data. This will enable new data-driven solutions and software services for factory equipment suppliers and operators. Unlike previous projects, Factory-X is being developed on the basis of eleven use cases, enabling implementation beyond the pilot phase. The project has been running since February 2024 and is funded by the BMWE (Federal Ministry for Economic Affairs and Energy). Our focus is on data consistency right from the engineering phase. This can save up to 60% of working time during machine development.

What does data consistency mean in industry?

Data is provided and utilised across different applications, roles and companies. The principle of a single point of truth is pursued, which strives for ideal data storage. It is the antithesis of data silos.

With the principle of the Digital Twin, the Industry 4.0 platform, a decoupling of data and application can be achieved. The main reason why this was not possible in the past is that no authorisations could be assigned within the data structures. Either someone had access to a certain data record or not at all. This was solved with the AAS (Asset Administration Shell) standard by the Industry 4.0 platform and prevents multiple images of an asset/component from having to exist and certain data from ending up in the wrong hands.

Why is this important for industry?

Around 200 project participants attended the mid-term event at SAP in Sankt Leon-Roth, Germany in early May including our colleagues Dr. Heiko Stichweh (Head of Technology, Innovation & Research) and Markus Kiele-Dunsche (Innovation Manager in the Technology, Innovation & Research department). "Factory-X creates an open ecosystem with secure cross-company data exchange," says Dr. Stichweh. "This has many advantages. The most important one is that the data room allows us to reach a much larger customer base with services and product data with clear added value for all parties. Digital business models will scale much better this way."

What has been achieved so far?

Factory-X has already reached a key milestone: the MX port (Manufacturing-X-Port) – the gateway to the industrial data room – is in place. The technical basis is a modular interface that can be easily integrated into existing IT systems and connected to machines. The Manufacturing-X approach is an alternative to the use of centralized cloud solutions, such as Google and Amazon, and the associated dependencies. The data remains distributed in the hands of the originators, the companies, and does not have to be stored on cloud platforms. The MX port enables data to be communicated directly between companies.

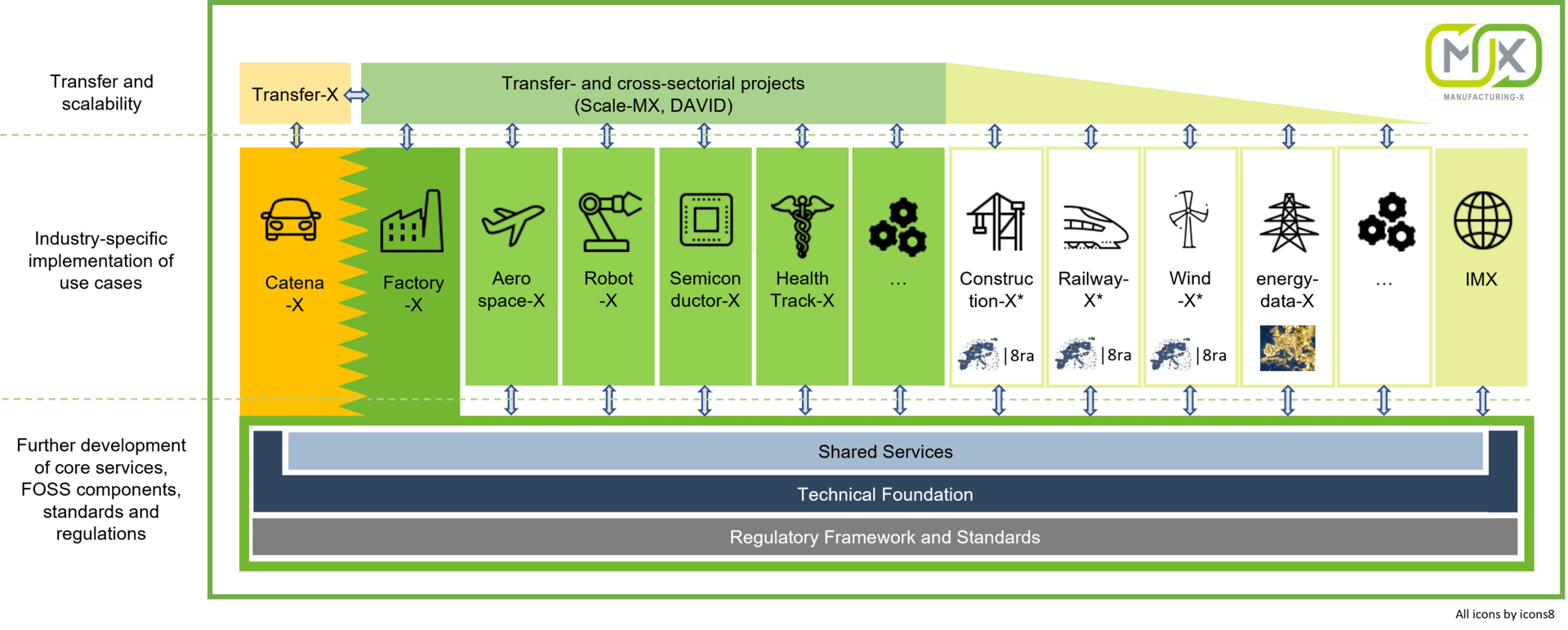

Picture: Manufacturing-X - Factory-X

Lenze Use Case: Integration of our tools into a consistent toolchain

At the mid-term meeting, the project partners used eleven use cases and initial demonstrators to show how companies can benefit from the data room. "Our focus is on the use case ‘Integrated Toolchains and Collaborative Engineering’. The aim is to enable an end-to-end toolchain into which the EASY System Designer and EASY Product Finder can be easily integrated. This gives developers direct access to all relevant data which saves an enormous amount of time and significantly simplifies engineering.", explains Markus Kiele-Dunsche.

What happens next?

In the second project phase, the focus is on the further implementation and integration of the use cases as well as the transfer of knowledge. The aim is to spread the message about the solution approaches and create the basis for broad scaling.