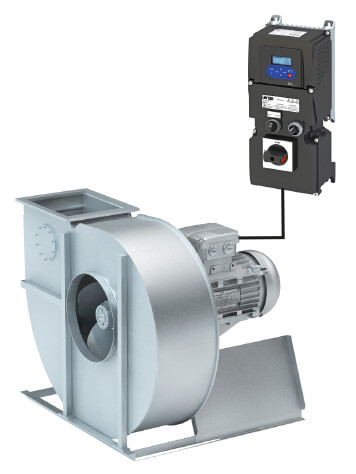

Lenze is your competent partner for VFDs from industrial installations to commercial buildings. The advanced drives are designed to optimize the performance of your air handling equipment, offering unparalleled control and energy savings. By adjusting motor speed to match the precise demands of your ventilation needs, Lenze VFDs reduce energy consumption and improve system reliability.

Whether upgrading or starting fresh, Lenze VFDs offer unmatched flexibility in power, communication, and installation – ideal for OEMs seeking customizable solutions.

![]()

Application Guide: Ventilation equipment with Lenze VFDs

![]()

Quick Start Guide: Ventilation equipment with Lenze VFDs

Lack of skilled personnel?

Quick installation and easy handling are guaranteed with Lenze VFDs to reduce the installation time by at least 30 minutes per VFD. Features like the memory module for parameterization, cable connectors and the intuitive interface make the commissioning easy and efficient. By adopting these innovative and dependable VFDs, you will observe a significant transformation in operational performance.

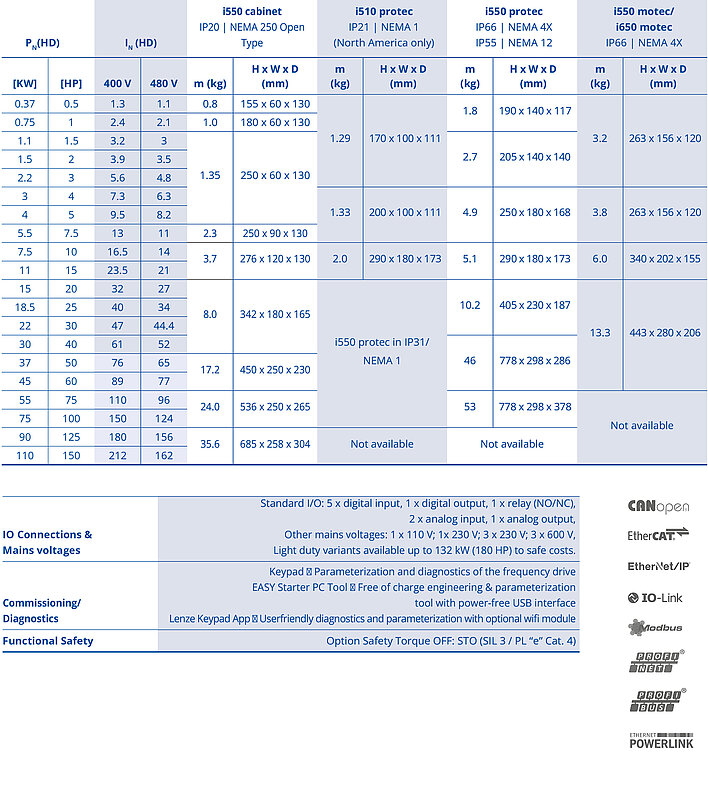

Fully scalable: The perfect drive for your application

Lenze VFDs offer compact size, integrated fan functions and power regeneration for temperature control, pneumatic conveying and clean environments which is a great fit for industrial blowers, air compressors and vacuum pumps.

To extract harmful particles in wood, metal processing, welding, and spraying with the help of filtration equipment Lenze VFDs enable PLC-free operation with sequencer control and compact design.

Critical ambient conditions apply for fan packs for cooling towers, chillers and condensers. They require robust VFDs with dynamic braking, de-icing, and quick installation features.

Blowers on industrial burners benefit from flexible installation, dynamic braking, and energy regeneration.

Farming ventilation ensures comfortable climate in livestock and produce storage. Here, drive features like belt loss detection and skip frequencies add real value.

For Building/HVLS Ventilation in large commercial buildings Lenze VFDs offer low motor noise and PID temperature control with sleep mode.

Industrial blowers, air compressors and vacuum pumps

Air handling equipment installed in industrial machines or processes for termperature control, pneumatic conveying, workpiece positioning, clean environment, etc.

Why Lenze VFDs?

- Support asynchronous and permanent magnet motors

- Integrated fan functions like PID control, power loss ride through and flying restart

- Compact size: Lenze VFDs are on average 40 % smaller

- i550 motec for motor mounting up to 45 kW (60 HP) with power regeneration and optional Lenze IE5 motor drive package

Filtration equipment

Extraction of uncomfortable or harmful fibers, dust, fumes, oil mist or particles from the air typical in wood, metal processing, welding, spraying, processes, etc.

Why Lenze VFDs?

- Compact size: Lenze VFDs are on average 40% smaller

- Integrated fan functions like PID control, and sequencer control etc. to allow PLC-free operation

- i550 motec for motor-mounting up to 45 kW (60 HP) with power regeneration

Fan packs for cooling towers, chillers and condensers

High power fan packs or process critical fan- packs in critical ambient conditions use VFDs instead of basic EC-fans.

Why Lenze VFDs?

- Robust operation thanks to dynamic braking with integrated brake-chopper

- Eco-friendly and easy to use power regeneration into the grid with i550 motec in case of windmilling effects or fast speed reduction

- Built-in fan functionality like de-icing, flying restart, power loss ride through and skip frequencies

- Connectorized solution for quicker installations

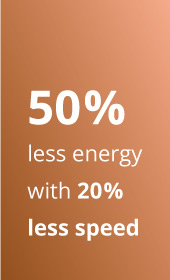

The energy saving potential of using VFDs vs. Direct-on-Line Operation (DoL) is commonly underestimated. Reducing the speed or air flow by 20% can lead to 50% energy savings. This is especially useful for applications with varying demand. Even fixed-speed applications, which are often oversized, can benefit from using a VFD with a demand-based PID controller. Energy cost saving with an 11kW fan sums up to € 3,000 (~3,300 USD) per year (@ 0.15 Ce/kWh).

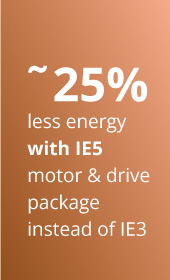

Moreover, Lenze VFDs are by design extremely efficient, meeting today’s and future EcoDesign Directives and further cutting energy bills. Additionally, reducing the speed of high inertia fans can be used for energy regeneration into the grids to save energy and installation costs of brake resistors. Finally, applying a Lenze IE5 motor and drive package can further reduce energy consumption by ~25% compared to an IE3 package.

Industrial burners

Blowers with VFD control on gas, oil, biomass or hydrogen burners to reduce electrical energy and fuel consumption.

Why Lenze VFDs?

- Supports asynchronous and permanent magnet motors

- Flexible installation with same look and & feel available as cabinet, wall-mounted or motor-mounted options

- Dynamic braking: with integrated brake chopper or eco-friendly and easy to use power regeneration into the grid with i550 motec

Farming ventilation

Reliable fan control with comfortable climate at lowest energy costs in applications like cow, pig, poultry and hatchery farming, or for the storage or ripening of fruits and vegetables.

Why Lenze VFDs?

- Supports asynchronous and permanent magnet motors

- Integrated fan functions like PID control, flying restart, power loss ride through, belt loss detection, skip frequencies, etc.

- Robust design: IP66 VFDs with NEMA 4X outdoor rating to withstand harsh environmental stress

Building/HVLS ventilation

For industrial and commercial buildings with demanding large ventilation equipment like kitchen ventilation or HVLS (High-Volume Low-Speed) ceiling fans.

Why Lenze VFDs?

- Supports asynchronous and permanent magnet motors

- Lowest motor noise: Skipping up to 3 frequency ranges or 16 kHz switching frequency

- PID – temperature control with sleep mode for lowest energy consumption